Sonke siyazi ukuba kwimveliso yeeprofayili ze-aluminium, inzuzo = ukuthengisa thabatha iindleko zemveliso.Ixabiso lilonke leprofayili ye-aluminium yahlulahlulwe kwiindleko ezisisigxina kunye neendleko eziguquguqukayo.Iindleko eziqingqiweyo ezifana nerenti yezityalo, ukuhla kwexabiso koomatshini, njl. iindleko eziguquguqukayo zinento eninzi yokuguquguquka.

Kwimeko yexabiso elifanayo lokuthengiswa kweprofayili ye-aluminium, ixabiso eliphezulu leprofayili ye-aluminium, iphantsi inzuzo.Okwangoku, phantsi kweemeko ezinzima zokunyuka kwamaxabiso ezinto eziphathekayo, ukunyuka kwemivuzo yabasebenzi, ukuxabisa i-RMB, ukunyuka kwamaxabiso amandla, ukwandisa umthwalo werhafu kunye nokunye, ukhuphiswano kwishishini elifanayo lingene "kumhlophe-kushushu" namhlanje.Ixesha lifikile lokulawula iindleko ezifanelekileyo.

Ukulawulwa kweendleko kuyisitshixo esilawulwa lishishini kunye nengundoqo.Kuphela ngokufumana rhoqo ikhonkco elibuthathaka, amandla angaphakathi kwemigodi, angasebenzisa zonke iindlela kunye nendlela yokunciphisa iindleko, ukuthatha inxaxheba ngokupheleleyo, ukuqala kwiinkcukacha, ukuqala ekunciphiseni inkunkuma, i-aluminium. isohlwayo ekuphunyezweni kolawulo lweendleko, inokwandisa ngokufanelekileyo isithuba sokuphila kweshishini, iphucule ubume bolawulo lweshishini, yenze ishishini libe nophuhliso oluzinzileyo, kwaye likwimo engenakuthintelwa.

Ulawulo lweendleko zeprofayili ye-aluminium lusekelwe kwikhonkco lexabiso njengesikhokelo, ulawulo lweendleko luhlukaniswe kwiindleko zokuyila, iindleko zokuthengwa kwempahla, iindleko zokuvelisa, iindleko zokuthengisa kunye neendleko zenkonzo.Ngenxa yokuba ulawulo lweendleko lubandakanya indawo ebanzi, umxholo uninzi.Ndiya kuthetha. malunga nendlela yokuphucula izinga leemveliso ezigqityiweyo ukusuka kwindawo yokujonga imveliso ukuze kuncitshiswe iindleko zemveliso.

Ngokuhlalutya idatha kunye nokusebenza, kubonakaliswe ukuba ukuphucula isivuno seprofayili ye-aluminium alloy yenye yezona ndlela zithe ngqo kwaye zisebenzayo zokunciphisa iindleko zemveliso.Ukuthatha i-workshop ye-extrusion njengomzekelo, iindleko zokuvelisa izinto ze-aluminium ziya kuncitshiswa nge-25-30 yuan ngetoni nganye ukuba isivuno sonyuswa ngepesenti enye yepesenti, kwaye inxalenye encitshisiweyo yinzuzo yoshishino.Ukuphucula i-extrusion. isivuno, umsebenzi wemveliso kukunciphisa inkunkuma extrusion.

Indlela yokuphucula isivuno seeprofayili ze-aluminium ukunciphisa inkunkuma ye-aluminiyam, ukuphucula imveliso, kunye nokunciphisa iindleko zemveliso yeeprofayili ze-aluminium, sishwankathele inkunkuma ekhutshiweyo:

Inkunkuma yeeprofayili ezigqithisiweyo ze-aluminium zinokwahlulwa zibe ngamacandelo amabini: inkunkuma yejometri kunye nenkunkuma yobugcisa.Inkunkuma yejometri yimveliso yenkunkuma engenakuphepheka yeeprofayili ze-aluminium alloy ngexesha le-extrusion.Njengokugqithiswa kwezinto eziseleyo, iimveliso zokwelula kuzo zombini iziphelo ze-chuck, ubungakanani bezinto akwanelanga ubude bezinto ezishiyiweyo, usike isampulu eyimfuneko, i-shunt edibeneyo yokufa kwigumbi le-shunt yebhloko eseleyo ye-aluminium, iingots kunye neemveliso zinqumle ubungakanani bezinto zesarha-blade. ukusetyenziswa kweetshiphusi ze-aluminium kunye nee-ingots ze-aluminium ezisetyenzisiweyo ngexesha lovavanyo lokubumba.

Inkunkuma yobuchwephesha yinkunkuma eveliswa bubuchwephesha obungenangqiqo, iingxaki zezixhobo kunye nokusebenza ngokungafanelekanga kwabasebenzi kwinkqubo yokuveliswa kweprofayili ye-aluminium alloy.Ukwahluka kwimveliso yenkunkuma yejometri, inokoyisa ngokufanelekileyo kunye nokuphelisa ukuveliswa kwemveliso yenkunkuma yobugcisa ngokuphuculwa kobugcisa kunye nolawulo oluqinisiweyo. .Inkunkuma yobuchwephesha inokohlulwa ibe:

Iimveliso zenkunkuma ye-tissue: ukutshisa ngokugqithiseleyo, i-ring grain coarse, i-gray grain, i-shrinkage yomsila, ukufakwa kwe-slag, njl.

Iipropati zeMechanical inkunkuma engafanelekanga: amandla, ubunzima buphantsi kakhulu, abuhambisani nemigangatho yesizwe;okanye iplastiki iphantsi kakhulu, ukuthambisa ngokwaneleyo akuhambelani neemfuno zobugcisa.

Iimveliso zenkunkuma engaphezulu: iileya, amaqamza, ukuqhekeka kwe-orenji, amagatya e-orenji, amabala amnyama, umgca we-welding longitudinal, umgca we-welding onqamlezayo, umkrwelo, ukucinezela isinyithi, njl.

Iimveliso zenkunkuma yobungakanani bejometri: amaza, ukujija, ukugoba, ukukhutshwa kwenqwelomoya, ubungakanani bokunganyamezeli, njl.

Ireyithi yeemveliso ezigqityiweyo ulwahlulo lwesantya sokulandelelana kwabasebenzi kwiimveliso ezigqityiweyo kunye nesivuno esibanzi.

Inkqubo egqityiweyo i-aluminium ratio ngokubanzi ibhekisela kwinkqubo ephambili, ngokuqhelekileyo isekelwe kwi-workshop njengeyunithi ye-calculation.Casting process (casting workshop), inkqubo ye-extrusion (inkqubo ye-extrusion), inkqubo yombala we-oxidation (i-workshop ye-oxidation), inkqubo yokutshiza umgubo (i-workshop yokutshiza ).Ichazwa njengomlinganiselo wesiphumo esifanelekileyo seworkshop kwigalelo lezinto ezikrwada (okanye iimveliso ezigqityiweyo) kwindawo yokusebenzela.

Umlinganiselo weemveliso ezigqityiweyo unxulumene nomgangatho wezixhobo, umgangatho we-ingot, isakhiwo semveliso, ukuphindaphinda kokutshintsha kweentlobo kunye neenkcukacha, iqondo eliphezulu lobuchwepheshe, inqanaba lolawulo lweshishini kunye nomgangatho wabaqhubi kunye nezinye izinto.

Isitshixo sokuphucula isivuno seprofayili ye-aluminium alloy kukunciphisa kunye nokuphelisa inkunkuma yeemveliso.Inkunkuma yejometri ayinakuphepheka, kodwa inokuncitshiswa.Inkunkuma yobuchwephesha yinto yomntu, enokupheliswa kwimeko-nge-case okanye iyancipha. .Ngoko ke, ulawulo olusebenzayo kunye nokuphuculwa kwesivuno seemveliso ezikhutshiweyo zingamkelwa.

Ukunciphisa inkunkuma yejometri kuyimfuneko ebalulekileyo yokuphucula isivuno seemveliso ezigqityiweyo

Amanyathelo okunciphisa inkunkuma yejometri

Ukhetho oluchanekileyo lobude be-ingot ngumlinganiselo oyintloko wokunciphisa inkunkuma yenkqubo.Ubude be-ingot abubalwanga emva kwe-extrusion, kodwa ibalwe emva kokukhutshwa.

Ngoku uninzi lwamashishini asebenzisa intonga ende eshushu yokucheba ialuminiyam intonga yokufudumeza iziko, xa kuthelekiswa nesithando somlilo esifutshane, ukunciphisa ilahleko yeetshiphusi ze-aluminium, ngenxa yokutshintsha kobunzima bodonga lokubumba, ubude bokuphosa bubhetyebhetye kwaye buchanekile, buphucula kakhulu. isivuno.Kodwa amashishini amaninzi kusetyenziso lweziko lokucheba intonga ende, aluhoyi ukubala ubude bokuphosa, kwaye ngokuthe ngqo anikezele umsebenzi kumqhubi ukuba alawule.Kwaye umqhubi uhlala esekelwe kumava phantsi kwebar yokuqala, qaphela ubude bezinto eziphathekayo, ukuba umehluko mkhulu, qhubeka ulungelelanisa, ngokuqhelekileyo kufuneka malunga nemivalo ye-3 ukuze ufumane ubude obuchanekileyo.Kwinkqubo, inkunkuma eninzi iye yaveliswa, okunciphisa kokubili ukusebenza kwemveliso kunye nesivuno.

Indlela echanekileyo kukuba ubude be-ingot bubalwa lisebe lokulawula inkqubo ngexesha lokuveliswa kokuqala kwesikhunta.Xa ukubunjwa kuveliswa kumatshini ngamaxesha amaninzi, ubude bentonga erekhodiweyo kwikhadi lokubumba bunyuswe kancinci malunga ne-5-10mm, kwaye ubude bezinto eziphathekayo bubonwa xa kuveliswa izinto.Ukulungiswa kakuhle ukuba kukho iyantlukwano.Ngoko intonga yesibini ichanekile kakhulu.Ngokwedatha ethile, isivuno seemveliso ezigqityiweyo sinokunyuswa ngepesenti ezi-4 zeepesenti ngokusebenzisa izikere ezinde ezishushu, kwaye kunokwenzeka ngokupheleleyo ukwandisa isivuno ngepesenti ezi-2 ukuya kwezi-3 ngokwenyani. imveliso.

Ukongezelela, inani lobude obumiselweyo okanye ubude bemveliso, ukwenzela ukuba kuqinisekiswe umsebenzi ophuculweyo we-extrusion phantsi kwesiseko se-extrusion.Xa ubude bebhedi ebandayo bubude ngokwaneleyo, kwandisa ubude bobukhulu obumiselweyo okanye ubude beemveliso kangangoko kunokwenzeka, oko kukuthi, ingot ende inokuthi ikhethwe.Kwakhona yindlela esebenzayo yokunciphisa ipesenti yenkunkuma yejometri kunye nokwandisa isivuno semveliso egqityiweyo.

Amanyathelo okuphucula izinga leemveliso ezigqityiweyo ukusuka kwinqanaba lobugcisa

Kubaluleke kakhulu umlinganiselo wobugcisa ukuphucula izinga leemveliso ezigqityiweyo ukuphucula umgangatho woyilo lokubumba kunye nokuveliswa kunye nokunciphisa i-Times yovavanyo lokubumba. Ngokuqhelekileyo akukho xabiso le-mold yokuvavanya i-1-3 ingots, ukwenzela ukuba isivuno sinciphise i-0.5-1 %, ngenxa yoyilo lokungunda, inqanaba lokuvelisa eliphantsi, ezinye iimveliso zokulungisa ukungunda, ukubumba amaxesha angama-3-4 okanye amaxesha amaninzi ukuvelisa iimveliso ezigqityiweyo, zinciphisa isivuno se-2-5% kuphela, nto leyo ayiyi kubangela kuphela uqoqosho. ilahleko, kodwa ngenxa yokuphinda-phinda uvavanyo lokungunda, iya kwandisa umjikelo wemveliso.

Ingqikelelo yovavanyo lomngundo yanamhlanje, oko kukuthi, emva kokuba ukungunda kuveliswa, akukho mfuneko yokuvavanya ukubumba, unokuthe ngqo kumatshini ukuvelisa iimveliso ezifanelekileyo.Ukusebenzisa isoftware yoyilo lokulinganisa, uhlalutyo lwento ephelelisiweyo, uyilo lunokugqitywa kwi Ikhompyutha.Inokuthi ivavanywe ngokulinganisa ikhompyutha.Ukusetyenzwa kwe-Mold cavity kugqitywe kwiziko lomatshini oluzenzekelayo, ukulungiswa kwe-mold yonke kukuchaneka okuphezulu, ngoko umgangatho wokubumba uphezulu kakhulu.Kumgangatho wokupasa komatshini ngaphezu kokungaphezulu 90%.Inokunyusa isivuno seemveliso ezigqityiweyo nge-2-6%.

Ukwandisa ngokufanelekileyo i-extrusion coefficient ye-aluminium ukuphucula isivuno

Umzi-mveliso we-aluminium ngamnye unoluhlu loomatshini, umzi-mveliso ngamnye ngokomlinganiselo we-extrusion wemveliso, ubude bebhedi ebandayo, icandelo langaphandle lemveliso, ubude be-extrusion cylinder diameter, ukumisela imveliso kumatshini ohambelanayo. imveliso.Ukuziqhelanisa kuye kwabonisa ukuba imilinganiselo efanayo yeemveliso, ifakwe kwiitoni ezahlukeneyo zokuvelisa umatshini we-extrusion, ngenxa ye-coefficient ye-extrusion eyahlukeneyo, isakhiwo sokwenziwa kwemveliso kunye nokusebenza kakuhle kwemveliso kunempembelelo enkulu, isivuno saso siya kuvelisa umahluko. I-tonnage yomatshini we-extrusion inkulu, i-coefficient ye-extrusion inkulu, izinga lemveliso eligqityiweyo liphezulu, kwaye ixabiso le-extrusion lisondele.

Ukuphucula umgangatho we-ingot ngumbono wokuphucula isivuno

Iingots zizinto ezibonakalayo zokuvelisa i-extrusion.I-ingots inesakhiwo esifanayo, iinkozo ezintle, akukho slag, iipores, ukwahlula, ukuqhekeka kunye nezinye iziphene, ezingenakukwazi ukunciphisa kuphela uxinzelelo lwe-extrusion, ukuphucula isantya sokukhupha, kunye nokuphucula umgangatho wangaphakathi weemveliso.Kwaye kunokunciphisa i-bubble surface yemveliso, iipores, imikrwelo, ukuqhekeka, imingxuma kunye nezinye iziphene.Ukufakwa kwe-slag encinci kunokukhutshwa nge-slit yebhanti yokusebenza kwe-mold, kodwa iya kubangela amanqaku epeyari kumphezulu weprofayili, okubangela ubude obuthile benkunkuma.Ukubandakanywa kwe-slag enkulu kuya unamathele kwi-slit yebhanti esebenzayo kwaye ayikwazi ukupheliswa, okuya kubangela iplagi yokubumba okanye iimveliso eziqhekezayo kwaye zithathe indawo yokubumba, okuya kuchaphazela kakhulu isivuno.Sebenzisa iipads ezihambelanayo xa usolula kwaye ulungelelanisa ukunciphisa ubude bokusika kwentloko kunye nomsila. impahla.

Iprofayili ekoluleni yolule, amashishini amaninzi awayila umqamelo ohambelanayo, ngakumbi iprofayili enkulu yokuxhoma kunye neprofayili engenanto.Ngenxa yoko, ukuguqulwa kwentloko kunye nomsila weprofayili kukhulu kakhulu, kwaye inxalenye yokuguqula kufuneka inqunyulwe xa ukubona imveliso egqityiweyo.Oku kubangele ukuhla kwezinga leemveliso ezigqityiweyo.

Umqamelo unokwenziwa ngokhuni oluqinileyo okanye iibhloko ze-aluminium.Uyilo lunciphisa ubungakanani be-cushion kunye nokwandisa ukuguquguquka kwayo.Kudonga olude kunye necandelo elivaliweyo leprofayili, ukuqondisa kwisigxina esivaliweyo kwi-pad kodwa kwakhona ukubeka isakhelo senkxaso kwinxalenye yodonga. ulwalathiso lobude luyancitshiswa.Ukulungiswa kufuneka kuyilwe, kulawulwe kwaye kukhokelwe ngabasebenzi abakhethekileyo.

Kwangaxeshanye, ukuze kuthintelwe into yokuba abasebenzi abazimisele ukusebenzisa umqamelo ngenxa yenkathazo, kufuneka simisele umvuzo kunye nendlela yokohlwaya ukuba izinga lemveliso egqityiweyo lidityaniswe nomvuzo.

Ukomeleza ulawulo lokufa kwe-extrusion kunye nerekhodi yemveliso yokuqala yeprofayili ye-aluminium.

Ikhadi lokubumba kunye nerekhodi yemveliso yokuqala ibaluleke kakhulu.Ikhadi lokubumba kufuneka likwazi ukubonisa ngokwenene imeko ye-nitriding ye-mold, imeko yokugcinwa kunye nemeko yezinto eziphathekayo.Ingxelo yokuqala kufuneka ikwazi ukubonisa ngokwenene ukuba ubunzima benkxaso, ubude bokuphosa kunye nobuninzi bubonelela ngesiseko esithembekileyo kwimveliso elandelayo.

Ngoku amashishini amaninzi aye aqonda ulawulo lwedatha yekhompyuter, kodwa kusekho indlela ende ekufuneka yenziwe kusetyenziso lokwenyani.

Nciphisa inkunkuma yejometri ngokusebenzisa i-afterextrusion engenasici

I-pad esisigxina igxininiswe kwintonga ye-extrusion ngaphandle kwe-extrusion ye-residual, kwaye ezimbini ziguqulwa kwinqanaba elithile.Xa i-cylinder ye-extrusion ingabuyi, i-pad yoxinzelelo ilula ukwahlula kwi-ingot.I-ingot elandelayo ityhilwa ngokuthe ngqo. kwikhatriji ye-extrusion.Ikhutshiwe kunye nentsalela ye-ingot yangaphambili, ngaloo ndlela kunqandwa imfuneko yokucheba ingoti nganye kube kanye.Ngokungqinelana neemfuno zomgangatho kunye nobungakanani bomyalelo wokumisela inani lokutshiza lokucheba. Ngokuqhelekileyo iziqwenga ezingama-40-50 zisikwa kwindawo ixesha.

Lungiselela inkqubo ye-extrusion yeeprofayili ze-aluminium ukunciphisa inkunkuma yobugcisa

Kukho iinkalo ezininzi ezichaphazela inkqubo ye-extrusion yenkunkuma yobugcisa, equka yonke inkqubo yokuvelisa i-extrusion.Ikakhulu ibandakanya: umgangatho we-ingot, ubushushu benkqubo, isantya sokugqithisa, izixhobo zokukhupha, ukufa, ukulayishwa kokugqithiswa kunye nokukhulula, unyango lokuguga, njl. uphuhliso oluphambili, iteknoloji yemveliso yenzululwazi, kodwa kunye nokuphunyezwa ngokungqongqo okuchanekileyo kweenkqubo zokusebenza, ukuphucula ubuchule babasebenzi kunye nemvakalelo yoxanduva.

Kangangoko kunokwenzeka ukunciphisa iindidi zemveliso kwishifti nganye, kukulungele ukulungiselela iintlobo ezi-3-5 kuphela kwi-shift nganye, ukuphucula imveliso yesethi enye yokubumba.Iindidi ezininzi kumatshini, i-aluminium yokubumba iya kuba athathiweyo, kokukhona asezantsi isivuno.

Isiphumo sokungunda kwisivuno ikakhulu sikwimiba emibini: uvavanyo lokungunda olutsha kunye nokusetyenziswa kokungunda kwemveliso.

Amaxesha amaninzi ukungunda kuzanywa, kokukhona i-aluminiyam ithathwa, kwaye isivuno sisezantsi.Ngoko kufuneka siphucule uyilo kunye nenqanaba lemveliso yokubumba.

Imveliso yokungunda kufuneka igcinwe ngononophelo, i-nitriding efanelekileyo, ukugcinwa ngexesha elifanelekileyo.Qinisekisa ixesha ngalinye kumatshini oqeqeshiweyo izinga liphezulu.Ukubumba okuhle kunye nokuqina okuphezulu.Ukuba utshintsho ngalunye ngenxa yokugcinwa kwesikhunta esingafanelekanga, okubangela ukuba iindidi ezi-3-4 kumatshini wokuvelisa ukusilela , izinga leemveliso ezigqityiweyo liya kuncitshiswa ubuncinane ipesenti enye.

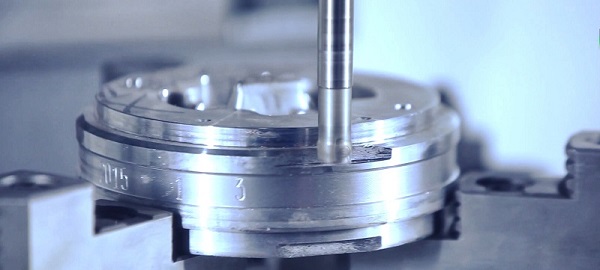

Izixhobo ze-aluminium extrusion zibandakanya: i-cylinder extrusion, intonga ye-extrusion, i-extrusion pad, i-fae pad, etc.Ikakhulu ukuqinisekisa ukuba i-cylinder extrusion, intonga, i-mold three concentric.Okwesibini, ukugcinwa okufanelekileyo kwe-cylinder extrusion, ukufudumeza okuchanekileyo, ukuqinisekisa ukuba isiphelo Umphezulu we-cylinder ugudile.Ukuphelisa zonke iintlobo ze-cylinder ye-extrusion kwaye ufe ngento embi.Coca i-aluminium eseleyo kudonga lwangaphakathi lwe-cylinder ye-extrusion rhoqo, khangela ukuba udonga lwangaphakathi lomngxuma lonakaliswe, sebenzisa i-pad yokufa ngokuchanekileyo, kwaye ukuphucula amandla enkxaso yokufa.

Ukushisa kwe-Extrusion, isantya sokukhupha kunye nokupholisa ezintathu, kwisakhiwo semveliso, iipropati zomatshini, umgangatho womphezulu unempembelelo enkulu, uya kuchaphazela kwakhona isivuno.Ukongezelela, ezi zintathu ziya kuchaphazela ubude bemveliso, ukushisa kwentonga yokuphosa kuphezulu, isantya se-extrusion sikhawuleza, izinga lokupholisa liphantsi, liya kwenza ubude bemveliso emva kokunyuka kwe-extrusion, izinga lokukhula lingafikelela kwi-0.5% - 1%, lichaphazela ukuxinana komgca weprofayili, ngoko inkqubo ezinzileyo ingakwazi ukuphucula isivuno.

Ukuphucula inkqubo ye-extrusion elandelayo ukuze ugweme inkunkuma yobugcisa.Ukukhupha inkqubo elandelayo yokuthutha, ngokukodwa ingqalelo kwiprofayili ye-scratch scratch.

Enye die extrusion porous inokuphucula isivuno seemveliso ezigqityiweyo.

Kwezinye iimveliso ezifanelekileyo kwi-multi-air extrusion, kangangoko kunokwenzeka usebenzisa i-porous extrusion, kungekhona nje ukunciphisa i-coefficient ye-extrusion, ukunciphisa kunye noxinzelelo, kodwa kunokuphucula isivuno.Ngaphantsi kwemeko yokuba inkunkuma yobugcisa i-zero, isivuno i-extrusion yemingxuma ephindwe kabini inokunyuswa nge-3% ~ 4% kunaleyo ye-extrusion yomngxuma omnye.

Isantya se-Extrusion yi-parameter yenkqubo ebalulekileyo kwinkqubo yokukhutshwa, ehambelana nomgangatho weemveliso kunye nemveliso ye-extrusion.Isantya sokugqithisa asifani nokuqonda ubushushu benkqubo, uhlobo lwe-alloy inkqubo yonyango lobushushu lunokukhetha ngokusisiseko ubushushu, kwaye isantya extrusion yinkqubo empirical kakhulu parameter.Different ingxubevange iinkangeleko kunye namacandelo ahlukeneyo anezantya ezahlukeneyo extrusion.Imveliso efanayo ichaphazeleka ngokutshintsha kweqondo lokushisa kwinkqubo ye-extrusion, kunye nezantya ze-extrusion zihluke ngaphambi nangemva kwe-extrusion.Ukulawula ngokuchanekileyo isantya se-extrusion, kufuneka kube:

Ngobuchule kunye nokuguquguqukayo ubambe uluhlu lwesantya se-extrusion ye-alloys ehlukeneyo, amacandelo ahlukeneyo (kubandakanywa nobukhulu bodonga), kwaye ubeke ingqalelo kwimpembelelo yesantya sokukhupha kwiiprofayili ze-aluminium, njengomgangatho womphezulu, idigri yokubumba, njl.

Uqhelene nesakhono sezixhobo ze-extrusion ukulawula isantya.Amanye ama-extruders anolawulo oluqhubekayo lwe-extrusion kunye nolawulo lwe-PLC, abanye banolawulo lwe-PLC kuphela, kwaye abanye abanalo. kunye nokunciphisa ngokuthe ngcembe i-billet kwi-cylinder ye-extrusion, uxinzelelo lwe-extrusion luyancitshiswa, isantya sokuphuma kwemveliso siya kukhawuleza kwaye sikhawuleze, ngamanye amaxesha senze imveliso emva kokuqhekeka.Ngoko ke, kuyimfuneko ukulungisa isantya se-extrusion.Kuphela ngo ukuqonda imeko yesixhobo sinokuthi isantya se-extrusion silungiswe ngokufanelekileyo kwaye silawulwe.

Qonda impembelelo yokubumba okuhlukeneyo kwisantya se-extrusion.Ngokuthetha ngokubanzi, isantya se-extrusion ye-flat die (iprofayili eqinile) iphezulu kunokohlulo lokufa (iprofayili engenanto) .Kodwa uhlobo olufanayo lokubumba, ukumila kwecandelo elifanayo lemveliso, ngenxa yoyilo kunye nenqanaba lokuvelisa lihlukile, isantya se-extrusion sihluke.Ngokukodwa, icandelo linomahluko obunzima bodonga, okanye iphrofayili ye-semi-hollow ene-open, enobudlelwane obukhulu kunye ne-mold.Kuphela isantya esithile se-extrusion esiyilwe ngumbumba sesona silungileyo.Isantya sikhawuleza kakhulu okanye sicotha kakhulu, kwaye kulula ukuvelisa ukujija nokuvula nokuvala.

Ukunciphisa ukuveliswa kwenkunkuma ngokomeleza ukuhlolwa kokuqala kunye nokuhlolwa kwenkqubo

Imilinganiselo yangaphandle yeemveliso zenkunkuma ye-aluminium, njengobunzima bodonga ngaphandle kokunyamezela, ukujija, ukukhutshwa kwenqwelomoya, ukuvulwa okanye ukuvala, njl., ikakhulu kuxhomekeke kwintonga yokuqala emva kovavanyo lokungunda ngumninimzi ekuhlolweni kokukhutshwa kunye nomhloli womgangatho. ekuhloleni ukuqina ukuthintela ukuveliswa kwenkunkuma enjalo.Ukunyamezelwa kobunzima bodonga ngokubanzi kufuneka kulawulwe ukusuka kunyamezelo olubi, kuba ngokuveliswa okuqhubekayo kweemveliso, ubukhulu bodonga lweemveliso buya kuba ngqindilili ngenxa yokuguga ngokuthe ngcembe kunye nokukrazula. yesikhunta.Iiprofayili ezinkulu zodonga, xa udweba kwaye ulungelelanisa ukujonga ngokucophelela umzobo, lawula inani elifanelekileyo lokwelula.

Inkunkuma engaphezulu efana nemikrwelo, i-orange peel, izicubu, amabala amnyama, amaqamza, kaninzi ayizizo zonke iimveliso zeengcambu zivelayo.Kuyimfuneko ukujonga omnye komnye ngomqhubi womkhosi, umhloli womgangatho kunye nenkqubo yokusarha yokwelula imveliso egqityiweyo, kunye nokulawula ngokudibeneyo ukukhutshwa kweemveliso zenkunkuma kumphezulu.

Ukuba umhloli womgangatho akafumani imikrwelo kwitafile yokukhupha, kwaye ufumana imikrwelo kwiimveliso ezigqityiweyo xa ebona, kuyimfuneko ukujonga inkqubo yokuguqulwa kwebhedi ebandayo ukuze ubone ukuba ezinye iinxalenye zebhanti yokuthutha, i-digger kunye nokunye. zinzima kwaye zivelele, zikhokelela kwimikrwelo.

Ulawulo lomgangatho lulawulo lwabasebenzi bonke kunye nenkqubo yonke.Inkqubo nganye kufuneka ibe nomgangatho omhle, ukwenzela ukuba ukuzihlola, ukuhlola ngokulinganayo kunye nokuhlolwa okukhethekileyo kunokudibaniswa, ukuze kupheliswe ngokufanelekileyo inkunkuma yobugcisa kwi-bud.Ukulawulwa kokwenziwa kunye nokuphucula isivuno.

Ngokusebenzisa la manyathelo angasentla kunokunciphisa inkunkuma yejometri, kunokubonwa ukuba ukuncitshiswa kwenkunkuma yejometri yimilinganiselo ebalulekileyo yolawulo lobugcisa kumashishini, enokubaluleka okukhulu kwiinzuzo eziphezulu zoqoqosho.

Ukuphucula isivuno se-aluminium extrusion billet kukugqiba kunye nenkqubo yokusebenza ngokucokisekileyo yemveliso ye-extrusion, kungekhona nje imiba yobugcisa kufuneka ibe kwindawo, kodwa kunye nemiba yolawulo kufuneka ibe yindawo.Kusekho indawo eninzi yeprofayili ye-aluminium yaseChina. amashishini ukuphucula isivuno, isivuno siya kuba yinkqubo eqhubekayo, ukuphucula isivuno kunye nokuphucula umgangatho wemveliso, imveliso inxulumene ngokusondeleyo.Ibuchwephesha beshishini kunye nenqanaba lolawulo lwe-embodiment ebanzi.

Phucula imveliso yealuminiyam enombala oxidized

Isivuno se-oxidation sisivuno semveliso enye, oko kukuthi, isivuno semveliso enye ngaphandle kokuphinda kusetyenzwe.Ngokwenkqubo yokuvelisa, iindleko zeeprofayili ezihlaziyiweyo ziphindwe kathathu kwiiprofayili ezingaphindanga ziphinde zenziwe, kwaye umgangatho ophezulu weeprofayili awukwazi ukuqinisekiswa.Ngokuqinisekileyo, umgangatho weemveliso ze-oxidized uqala kwi-workshop yokuphosa.Ngenxa yezithintelo zendawo, oku kulandelayo yintetho emfutshane malunga neenkcukacha ezithile ekufuneka ziqwalaselwe kwinkqubo yokuvelisa i-oxidation.

I-screw phakathi kwentonga yokuxhoma kunye ne-conductive beam kufuneka iqiniswe rhoqo.Ngaphambi kokubopha izinto eziphathekayo, kufuneka siqale sihlolisise ukuba intonga yokuxhoma igxininisekile.Ukuba ikhululekile kancinane, kufuneka iqiniswe ngexesha.Enye i-corrosion, intonga yokuxhoma iya kuba yincinci, idinga ukutshintshwa ngexesha, kuba indawo yayo yokuhambisa incinci, kulula ukubangela ukushisa, kwangaxeshanye ukubopha, ukukhusela Iprofayili ewela kwi-slot ebangelwa yipali, umonakalo omfutshane wesiphaluka kunikezelo lwamandla.

Kwangaxeshanye iwele kwiprofayile yetanki kufuneka icocwe kwangexesha, njengetanki yokuhlamba yealkali ibe yiprofayile, iya kuhlwa kungekudala, uvavanyo lubonakalise ukuba ukusetyenziswa kwealkali kuyalingana nokuhlamba kwealkali kwe50-100. ingcambu yeprofayili yokusetyenziswa kwe-alkali.Ukuwela kwitanki yombala okanye itanki yokutywina, ngenxa yokubola, itanki iya kuqokelela inani elikhulu le-ion aluminium, echaphazela ubomi benkonzo ye-tank liquid.

Izinto zokubopha ngocingo lwe-aluminiyam kunye neentlobo ezimbini zenkcazo zilungile, i-aniseed yokukhetha ucingo lwe-aluminiyam olurhabaxa, imathiriyeli ephakathi kunye nencinci isetyenziselwa i-aluminium ecikizekileyo, ingasetyenziselwa i-2mm kunye ne-3mm, okanye i-2.2mm kunye ne-3.2mm iindidi ezimbini zenkcazo, i-aluminium. ukuqina kocingo lokuvala kuthatha i-1/2~3/4 kulungile.Okwangoku, amashishini amaninzi aguqulelwe kwijig.

Ngaphambi kokuxhoma kwitanki ye-oxidation ukuze uqinise iprofayili nganye; Izinto zokuphinda zisebenze phambi kwe-oxidation yezinto eziphathekayo, ukusebenzisa i-pliers ukubetha isiphelo seprofayili ukwenza i-shift phambi kwezinto, ukuze uqhagamshelwano ngaphandle kwefilimu, ukuqinisekisa ukuhanjiswa okulungileyo. .

Chwetheza imathiriyeli ejinga kwitanki oxidation kunye netanki yombala isihlalo conductive kufuneka ingqalelo ekunene, kungenjalo ethambekele kwi Yin kunye Yang ibala umahluko.

Emva kokuba isiphelo samandla e-oxidation sinqunyanyisiwe ngexesha, ukuhlala kwitanki ye-oxidation imizuzu embalwa kuya kuchaphazela umngxuma wokutywina, kuya kwenza isantya sombala;Emva kwe-oxidation, iyaphakanyiswa kwaye ithotywe emoyeni ixesha elide.Esinye isiphelo sesisombululo sokunciphisa i-asidi simnyama ngenxa yokwandiswa kwepore yefilimu ye-oxide, kwaye umehluko wombala kuzo zombini iziphelo kulula ukuvela.

Ixabiso le-pH lamatanki okuhlamba amanzi amane ngaphambi nangemva kwetanki yombala kufuneka igcinwe ngokuzinzileyo.Ixabiso le-pH lamatanki amane okuhlamba amanzi aqhelekileyo alawulwa ngolu hlobo lulandelayo:

Ixabiso le-pH lokuhlambela kwamanzi okuqala emva kwe-oxidation: 0.8 ~ 1.5

Ixabiso le-pH lesibini lokuhlambela amanzi emva kwe-oxidation: 2.5 ~ 3.5

Ixabiso le-pH lokuhlambela kwamanzi okuqala emva kombala: 1.5 ~ 2.5

Ixabiso le-pH yetanki yesibini yokuhlamba emva kombala: 3.5 ~ 5.0

Kwiimeko eziqhelekileyo, umlinganiselo othile wamanzi aphuphumayo uvulwa ngexesha lokuvelisa, kwaye i-valve yokungena ivaliwe ngexesha xa ukuveliswa kumisiwe.Akufunekanga ikhuphe amanzi okanye yongeze amanzi kwitanki yonke.Ukuba amanzi ahlala kwi-tank yokuqala yokuhlamba emva kwe-oxidation imizuzu embalwa, isantya sombala siya kukhawuleza, kwaye ukuba amanzi ahlala kwi-tank yesibini yokuhlamba, umbala uya kuncipha.

Ukuveliswa kwezixhobo zentsimbi ezikhanyayo, indlela yombala iyamkelwa ngokubanzi kuqala, emva koko ibuyele kwipleyiti yombala eqhelekileyo.Ngenxa yokwahlukana kombala wentsimbi yokulinganisa ixesha lokulawula ixesha lincinci kakhulu (imizuzwana emi-2 ~ 3 kuphela) , kwaye ukusebenzisa umgaqo ophelayo unokuba ne-10 ~ 15 imizuzwana yexesha lokulawula umbala, kwaye ukufiphala okudityanisiweyo kukwanceda kumbala ongasemva ofanayo, ukulinganisa intsimbi ephelayo kunye nemibala ehambelanayo inombala ithande ukujika luhlaza, kwaye umbala wexesha elinye uthande ukujika. ibebomvu.

Uhlobo lwezinto ezixhonywe kwitanki yombala kunye netanki yokuqala yokuhlamba emva kokufakwa kwemibala emva kokuxhoma musa ukuyeka ixesha elingenanto lide kakhulu, kungenjalo umphezulu weprofayili uya kuvela irebhoni, umbala ongalinganiyo kunye nokuphela komlambo wento emhlophe, kufuneka ibe kancinci kumbala we ukuhlamba okulandelayo ngexesha, umbala oluchanekileyo kufuneka kuhlanjwe yesibini emva.Ngokuthetha ngokubanzi, izinto zentsimbi ukulinganisa, ezifana template umahluko umbala obomvu, ibonisa ukuba ixesha imibala akwanelanga ukuba umphelelisi umbala; Ukuba umbala omthubi. , ifakwe umbala, ngokobunzulu bombala, ungakhetha ukuhlehla kwitanki yombala okanye kwitanki yokuqala yokuhlamba emva kombala.

Indlela yokongeza iziyobisi kwitanki yombala: i-sulfate ye-stannous kunye ne-nickel sulfate kufuneka ichithwe kwitanki, kwaye isongezo sombala kufuneka sinyibilike emanzini acocekileyo (amanzi acocekileyo ayanyibilika).Kufuneka kuqatshelwe ukuba isongezelelo esiqinileyo sinokugalelwa emva kokuchithwa ngokupheleleyo, kwaye i-asidi ye-sulfuric concentrated ingagalelwa ngqo kwitanki yombala.

Ubushushu, ixesha kunye nomgangatho wamanzi okuhlamba amanzi ashushu phambi kokuba i-electrophoresis iqinisekiswe.Ukuba intsalela ye-SO42- kumngxuma wefilimu ye-oxide ayihlanjwanga, ukutyheli kunye ne-opacity yefilimu yepeyinti kunokwenzeka ukuba yenzeke emva kwe-electrophoresis kunye nokubhaka.Phantsi kweemeko eziqhelekileyo, ubushushu bamanzi ashushu bulawulwa kwi-60 ~ 70 ℃, kunye nokuhlamba kwamanzi ashushu. ixesha yi 5 ~ 10 imizuzu.

Ixesha lokuposa: Mar-26-2021