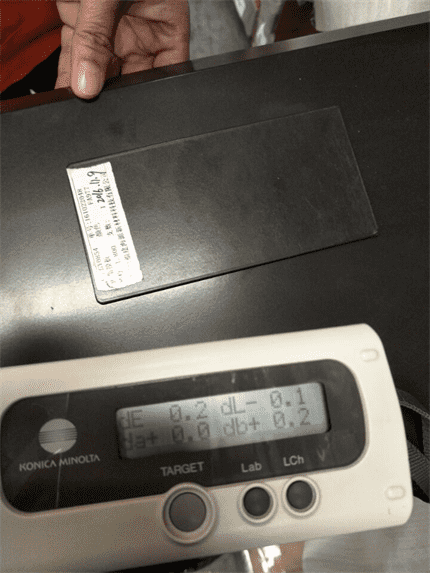

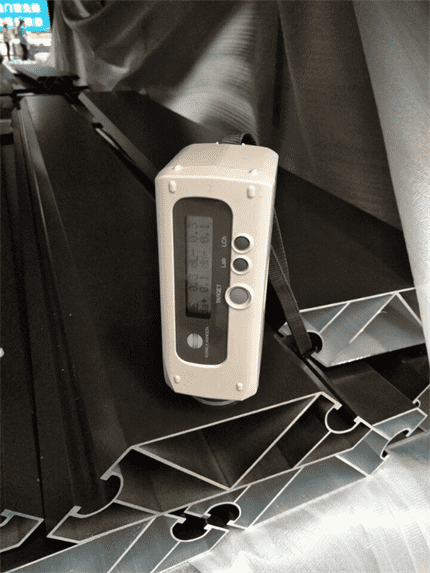

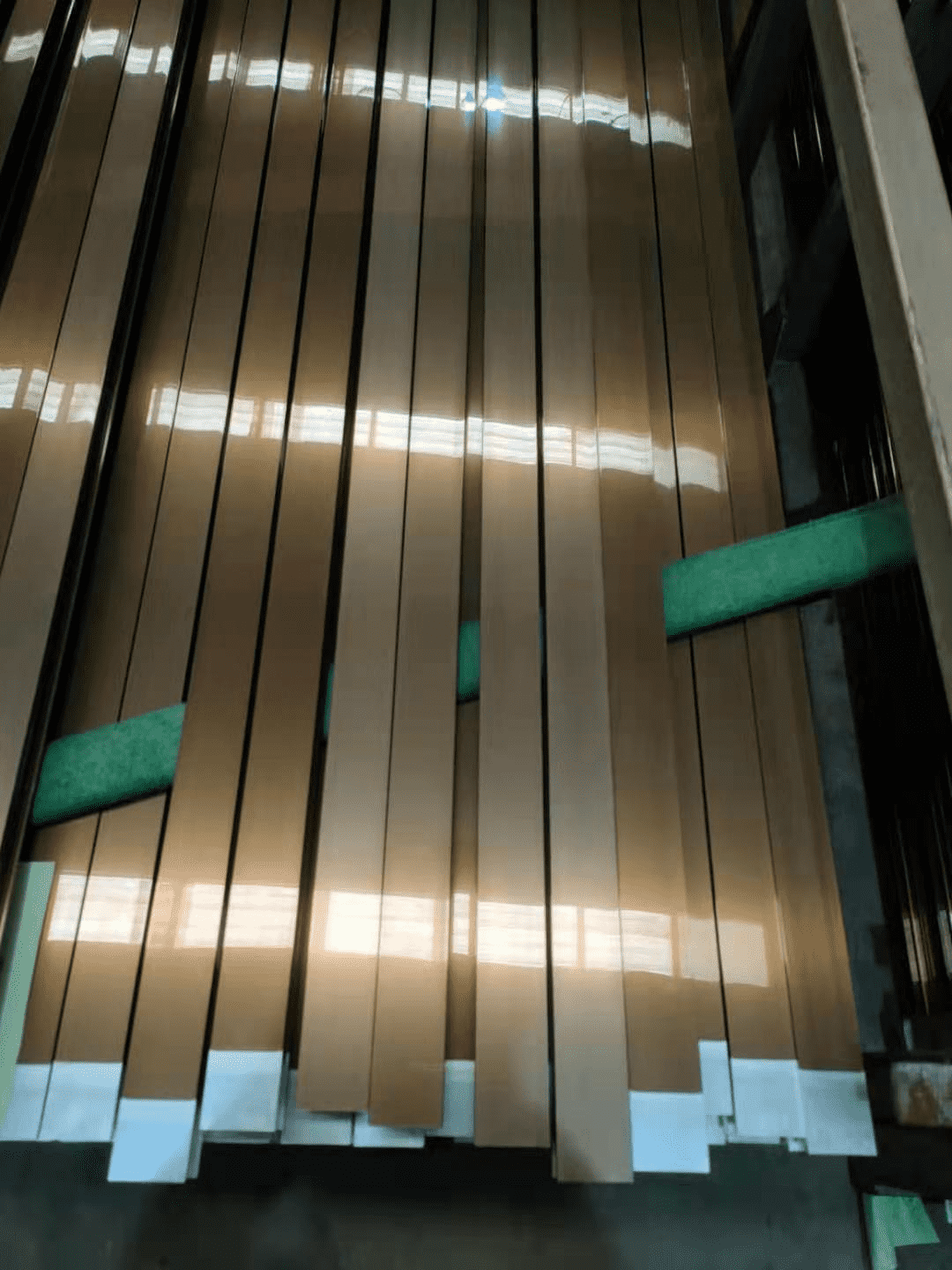

Iziphene zombala we-aluminium ngokubanzi zineemeko ezilandelayo: umbala okhanyayo, umehluko wombala, ukudaya, ibala elimhlophe, elimhlophe, ukudaya, ukuphunyuka kombala, njl. Indlela yokusombulula le ngxaki ukuze kuqinisekiswe ukuba umehluko wombala webhetshi nganye yeemveliso uhlala uhambelana kwaye phakathi koluhlu lokutenxa okuqinisekisiweyo ngamaqela omabini ukuhlangabezana neemfuno zabathengi.Oku kufuna ukuba amashishini emveliso afunde kwaye agade ngokuchasene ne-electrochemical coloring surface treatment of profiles.

Isizathu kunye nonyango lombala okhanyayo kunye nokwahlukana kombala

1. Ubukhulu befilimu ye-oxide ayilingani.Isizathu esinokuthi ubushushu kunye noxinzelelo lwe-anodic oxidation tank liquid alulingani.Ngeli xesha, ulwelo lwetanki kufuneka luxutywe ngomoya ocinezelweyo ukusombulula ezo ngxaki.

2. Ukushisa okanye ukuxinwa kwesisombululo sedayi akulingani.Inkqubo yokuxuba yaziswa kwaye amaxesha okuxuba anyuswa.

I-3, isantya sokudaya sikhawuleza kakhulu.I-bottom ye-workpiece yokuqala kwisisombululo sedayi kwaye ekugqibeleni ishiye isisombululo sedayi, ngoko ke i-bottom iyona nto ilula kakhulu ukudaya ubunzulu.Isisombululo kukulungelelanisa idayi edibeneyo, ukwandiswa okufanelekileyo kwexesha lokudaya.

I-4, i-conductivity yombane engalunganga.Inokuthi ibangelwa ngama-hangers avulekileyo, ingqalelo ukuxhoma kunokuphepha iingxaki ezinjalo

I-5, idayi ibhityile kakhulu, inokongezwa ukuphucula ugxininiso.

6. Ubushushu besisombululo sedayi buphantsi kakhulu.Isisombululo sedayi sinokufudumala ukuya ngaphantsi kwe-60 ℃.

I-7, idayi inyibilika ngokungafanelekanga, okanye kukho idayi enganyibilikiyo edadayo, kulula ukuvelisa umahluko wombala.Isisombululo kukuphucula ukunyibilika kwedayi.

Iimbangela kunye nonyango lokungaphumeleli kokudaya

1. Ubukhulu obunganeleyo befilimu ye-anodic oxidation.Isisombululo kukukhangela ukuba inkqubo ye-anodic oxidation isemgangathweni, ukubona ukuba iqondo lokushisa, i-voltage, i-conductivity kunye nezinye izinto zizinzile, ukuba zingaqhelekanga, nceda ulungise inkcazo ehambelanayo, ukuba akukho. ukungaqhelekanga, kunokwandiswa ngokufanelekileyo ixesha le-oxidation, ukuqinisekisa ukuba ubukhulu befilimu bufikelele kumgangatho.

2. Ixabiso le-pH lesisombululo sedayi liphezulu kakhulu, ngeli xesha, i-glacial acetic acid ingasetyenziselwa ukulungelelanisa ixabiso le-pH kwixabiso eliqhelekileyo.

3. Emva kwe-oxidation, i-workpiece ifakwe kwi-tank ixesha elide kakhulu.Gqwetha ukudaya ngexesha elifanelekileyo, ukuba le meko yenzekile, i-workpiece ingafakwa kwitanki ye-anodic oxidation okanye i-nitric acid neutralization ye-neutralization ye-activation efanelekileyo kwaye idaywe, umphumo. kuya kuba kuhle kakhulu.

4. Ukukhetha okungafanelekanga kwedayi.Idayi efanelekileyo kufuneka ikhethwe.

I-5, idayi iye yachithwa okanye i-mold, ngeli xesha kufuneka ithathe indawo yedayi.

I-6, ubushushu be-oxidation buphantsi kakhulu, okubangela ubuninzi befilimu yesikhumba.Ubushushu be-oxidation bunokwandiswa ngokufanelekileyo.

I-7, i-conductivity yombane engafanelekanga.Ukwenzeka kokungahambi kakuhle kwebhetshi njengoko kuboniswe ngoqhagamshelwano olubi lwe-anode yobhedu okanye i-cathode lead plate.Nika ingqalelo ukucoca intonga yobhedu ye-anode kunye ne-cathode lead plate ukuze uqinisekise ukuqhuba kakuhle.

Izizathu kunye nonyango lwamabala amhlophe kunye nokuvezwa

1, amanzi akacocekanga, amanzi kufuneka aqiniswe.

2. Amanzi asetyenziselwa ukuhlamba amdaka kakhulu kwaye kulula ukungcolisa ifilimu.Ngeli xesha, amanzi kufuneka atshintshwe ukuze kuqinisekiswe umgangatho wokuhlamba.

3. Ifilimu ye-oxide ingcoliswe ngumsi kunye nothuli emoyeni, i-asidi kunye nenkungu ye-alkali.Ukuhlamba okuphuculweyo, ukudaya ngexesha elifanelekileyo, ukuhanjiswa kwexesha kunokunciphisa kakhulu le mpawu.

I-4, ifilimu ye-oxide ingcolile ngeoli kunye ne-sweat stains.Kufuneka uqinise ukukhuselwa, ungathinti ukubonakala kwe-workpiece ngesandla.

5. Kukho ukungcola okungenakunyibilika kwisisombululo sedayi, ezonakaliswe yioli kwaye zitshabalalise ukudaya okuqhelekileyo.Ngeli xesha, isisombululo sedayi kufuneka sihluzwe okanye sitshintshwe, kwaye i-tank liquid kufuneka ihlambuluke rhoqo.

I-6, i-gap workpiece, i-asidi esele yomngxuma enzulu iphuma ngaphandle, ukomeleza ukuhlamba olu hlobo lomsebenzi.

7,Isisombululo sedayi singcolisekile kwaye sibangela ukubola komngxuma wesixhobo esidayiweyo.Ngeli xesha, idayi kufuneka itshintshwe.

Iimbangela kunye nonyango lokudaya inhomogeneity

1. Ixabiso le-pH lesisombululo sedayi liphantsi, kwaye i-dilute ammonia amanzi inokulungiswa kwixabiso eliqhelekileyo.

2, ukucoca akucocekanga.Amanzi kufuneka ahlanjwe kakhulu.

I-3, idayi ayichithwanga ngokupheleleyo, yomeleza ukuchithwa ukugqiba ukuchithwa.

4, ubushushu bedayi buphezulu kakhulu, nciphisa ubushushu.

I-5, i-pore yefilimu ye-oxidation incinci, isizathu kukuba ukushisa kwe-oxidation kuphantsi kakhulu, inqanda ifilimu yesikhumba ichithwa yi-asidi ye-sulfuric, inokulungelelaniswa ngokufanelekileyo kwiqondo lokushisa eliphezulu le-oxidation ukuphepha le ngxaki.

I-6, ukudaya kunye nokubala imibala ngokukhawuleza, kwaye ixesha lokudaya lifutshane kakhulu, idayi ye-dilute inokulungelelaniswa, ukunciphisa ubushushu bokudaya, kufanelekile ukwandisa ixesha lokudaya.

I-7, iqondo lokushisa lokutywina liphantsi kakhulu, isisombululo sokufudumeza.

8. Ukuba ixabiso le-pH lesisombululo sokutywinwa komngxuma liphantsi kakhulu, lihlengahlengise kwixabiso eliqhelekileyo kunye ne-dilute ammonia yamanzi.

9. Umphezulu odayiweyo kulula ukucima.Isizathu esiphambili yifilimu erhabaxa, ngokuqhelekileyo ubushushu be-oxidation buphezulu kakhulu.Ingqalelo kufuneka ihlawulwe ukulawula ukushisa kwe-oxidation ngaphakathi koluhlu oluqhelekileyo.

Kwiziphene zemibala ye-oxidation yeenwele, thatha amanyathelo ahambelanayo, umgangatho weemveliso zombala we-aluminium kufuneka ukwazi ukulawula ngokuzinzile, ukuhlangabezana neemfuno zokwaneliseka kwabathengi.

Ixesha lokuposa: Apr-02-2021