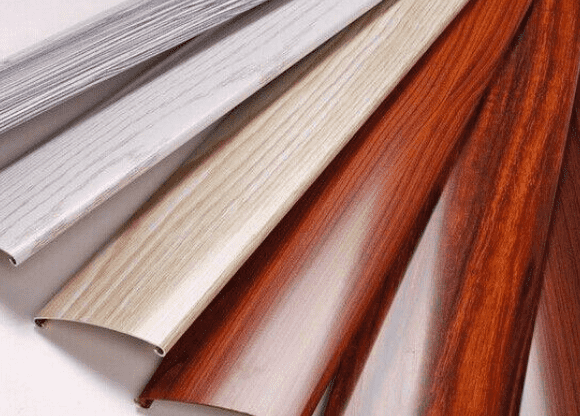

Aluminiyam ingxubevange iinkozo ipeyinti unako ukufikelela 99% isiphumo ukulinganisa iinkozo iinkuni, ibhrashi iinkozo ipeyinti kwi aluminiyam ingxubevange, ialluminiyam ingxubevange ibe nombala oqaqambileyo, ngokungathi ungabona isiphumo iinkuni iinkozo.Isakhiwo aluminiyam ingxubevange emva Ukusetyenziswa komhombiso wepeyinti yeenkozo zokhuni kuya kwenza umntu azive ebuyela kwihlathi lakudala, indawo yendalo engqongileyo yantlandlolo, kodwa nakwindawo engqongileyo yongezwe kakhulu, ngoku ibrashi yepeyinti yeenkozo zomthi kwi-aluminium alloy iye yaba yifashoni kunye nomkhwa icandelo lobunjineli.

Namhlanje inkqubo yokupeyinta iinkozo iinkozo kunye nokulinganisa iinkozo iinkuni sele yamkelwe luluntu kunye nokusetyenziswa, kwaye wayethandwa ngokunzulu kuthi, Zhejiang Hong Shan art ukutyabeka iinkuni ipeyinti okuziinkozo ibrashiwe Lao shifu kwinkqubo yokwakha non-netyhefu, incasa, akukho ungcoliseko, umthi we-aluminiyam wepeyinti yepeyinti encamathelayo ubume bezulu obuphezulu, kwangaxeshanye awukwazi kuphela ngaphakathi endlwini, ngaphandle kwe-aluminiyam yokhuni i-lacquer ithandwa kakhulu.

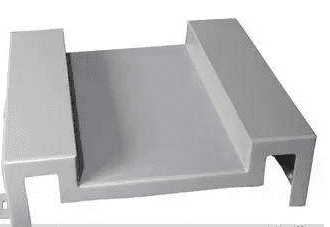

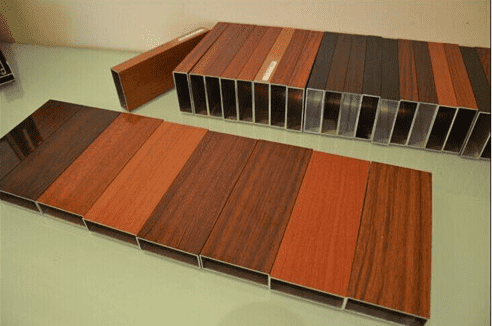

Iprofayile yoshicilelo yoshicilelo lwezinkozo zokhuni ibhekiselele kwisiseko sokutshiza ngomgubo we-electrostatic, ngokomgaqo wobushushu obuphezulu be-Hua Hua ukungena kwe-thermal, ngokufudumeza, uxinzelelo, iphepha lokudlulisa okanye ifilimu yokudlulisa kwipatheni yeenkozo zomthi, ukudluliselwa ngokukhawuleza kunye nokungena kuye kwatshizwa. kwiprofayili.Ukuze ukuveliswa kweprofayili yeprofayili yomthi ecacileyo, ingqiqo ye-dimensional-dimensional yomelele, inokubonakalisa imvakalelo yendalo yengqolowa yomthi, yinto efanelekileyo yokugcina amandla kunye nokukhusela okusingqongileyo endaweni yomthi wendabuko.

Ingqolowa yokhuni ine-adhesion eqinile kwi-aluminium, i-non-toxic, akukho vumba elikhethekileyo, kulula ukuyicoca.Imigca yemveliso icacile kwaye ifana nobomi, ingqiqo ye-dimensional-dimensional yomelele, umphumo wokuhombisa inkangeleko ulungile, kukho ukubuyiswa kokulula, isiphumo esibonakalayo sokubuyela kwindalo.Ifilimu yokugquma phezu kweprofayili ye-electrostatic yokutshiza i-aluminium ayiguqukiyo kwaye ayinayo i-oxidizing emoyeni, ngaphandle kongcoliseko lwendalo. buyisela i-lister yokuqala kunye nenkangeleko.

Ezi nkcukacha zilandelayo zenkqubo yoshicilelo lokudluliselwa kweenkozo zokhuni.

Inkqubo 1: ifanelekile kwindawo enkulu okanye i-substrate ekhethekileyo.

Inyathelo 1: Khetha imathiriyeli esisiseko etshiziweyo

Inyathelo lesibini: ngephepha iinkozo zokhuni transfer ubushushu ukuba idluliselwe kwi substrate esongelwe, kunye nobushushu obuphezulu enamathelayo encamathelayo ujongano lwephepha esisigxina, ukuze kuthintelwe iinkozo iinkuni transfer ubushushu iphepha ukukhulula. iphepha kufuneka lincanyatheliswe ngobuso be-substrate ukuba idluliselwe.)

Inyathelo lesithathu: kwaye emva koko kwiplanga lokutshintshela ubushushu lenkuni lilisongelwe kwi-substrate yeplastiki yeplastiki ityhubhu enokumelana nobushushu obuphezulu kunye nokutywinwa okuhle, kwaye ke vacuum ukusuka kwiziphelo ezimbini zeplastiki yeplastiki, de ingxowa yeplastiki inokuba ngokupheleleyo nangokufanelekileyo kufutshane ne-substrate.

Vacuum ubungakanani boxinzelelo olungalunganga kufuneka lusekelwe kwiimpawu ze-substrate kunye neengxowa zeplastiki zikwazi ukumelana noxinzelelo olubi kunye nezinye izinto zokwenza uhlengahlengiso olufanelekileyo, ngokuqhelekileyo phakathi kwe-0.3 ~ 0.8Mpa.(Qaphela: injongo yokusebenzisa iingxowa zeplastiki kukunyanzela iinkozo iphepha lokudlulisa i-thermal ukuba lifakwe ngokupheleleyo kwaye ngokufanelekileyo kwi-substrate ngoxinzelelo olubi.)

Isinyathelo sesine: i-substrate ifakwe kwi-oven yokubhaka, ubushushu bokubhaka kunye nobude bexesha kufuneka bulungelelaniswe ngokweempawu ze-substrate eziza kudluliselwa, ukuhambisa ubunzulu bokuthungwa kunye nokusebenza okuthe ngqo kwe-oven kunye nezinye ezibanzi. izinto, ngokuqhelekileyo iqondo lobushushu 160 ~ 180℃, ixesha 5 ~ 8 imizuzu

Inyathelo lesi-5: Khupha i-substrate edluliselwe kwi-oven, ukhuphe ingxowa yeplastiki ukusuka kwelinye icala le-substrate edluliselweyo (Qaphela: le ngxowa yeplastiki ingasetyenziselwa inzuzo), krazula iphepha lokuhambisa ubushushu; kwaye ucoce umphezulu.

Inkqubo yesibini: ilungele i-substrate ecaba.

Inyathelo 1: Khetha isubstrate etshizwe nge-electrostatic

Inyathelo lesibini: umphambili wephepha lokuhambisa ubushushu benkozo kunye nenxalenye esezantsi eza kudluliselwa ebusweni bevenkile.

Inyathelo lesithathu: ipleyiti yokutshintsha ubushushu bomatshini woxinzelelo, ukufudumeza, ngokuqhelekileyo ukuhambisa ubushushu be-160 ~ 180 ℃, ixesha le-18 ~ 25 imizuzwana.

Isinyathelo sesine: krazula iphepha lokudlulisa i-thermal, sebenzisa ukuhanjiswa kwefilimu ye-PET thermal transfer,

Inkqubo yesithathu: ifanelekile kwi-substrate ekhethekileyo.

Inyathelo 1: Khetha isubstrate etshizwe nge-electrostatic

Isinyathelo sesibini: kunye nefilimu yokudlulisa thermal ye-PET ukuba idluliselwe kwi-substrate esongiweyo, kunye nomatshini wokutywina we-ultrasonic ifilimu yokudlulisa thermal ye-PET itywinwe kwingxowa ye-tubular. ubuso bodluliselo lwencama.)

Isinyathelo sesithathu: i-vacuum ukusuka kuzo zombini iziphelo ze-tubular PET isikhwama sefilimu yokudlulisa i-thermal de ifilimu ye-PET yokudlulisa i-thermal ingasondela ngokupheleleyo kunye nempumelelo kwi-substrate. inokumelana noxinzelelo olubi kunye nezinye izinto ukwenza uhlengahlengiso olufanelekileyo, ngokuqhelekileyo phakathi kwe-0.3 ~ 0.8MPa

Isinyathelo sesine: i-substrate isongelwe kwi-oven ukubhaka, ubude beqondo lokushisa lokubhaka kunye nexesha kufuneka luhlengahlengiswe ngokweempawu ze-substrate eziza kudluliselwa, ubunzulu bokuthungwa okuza kudluliselwa kunye nokusebenza okuthe ngqo kwe-substrate. I-oveni kunye nezinye izinto ezibanzi, ubushushu boshicilelo oluqhelekileyo lokudluliselwa yi-160 ~ 180 ℃, ixesha yi-5 ~ 8 imizuzu.

Inyathelo lesi-5: ukukhupha kwi-oven kudluliselwe kwi-substrate, ngokuvuthela ngesandla okanye ngoomatshini (oko kukuthi, ngokuvuthela ifilimu ye-PET thermal transfer tubular bag blowing explosion) ngaphezu kwe-PET thermal transfer.

Ixesha lokuposa: May-21-2021